Projects

From entrepreneur to start-up company. In 1995, KTH Energy Processes was approached, and a feasibility study was carried out in a collaboration between LimeArc-cofounder Roland Lundqvist and the European energy company Vattenfall AB. This resulted in two Swedish patents shortly after the turn of the millennium. Electric heating is effective in high temperature processes and electrically generated plasma was identified as an effective and beneficial way to supply the large amounts of energy required. Roland Lundqvist (with a research partner) has worked with the concept to take it from the idea stage to becoming a feasible process and a globally available product.

The feasibility study took into account issues related to process integration. A parallel module with Gasplasma should preferably produce a lime comparable to lime from existing rotary kiln processes so that it can be integrated with existing causticization. The feasibility study indicated that the lime mud was burned in a few seconds in a reactor with one hundredth in volume compared to today’s fuel-fired rotary kilns. The gas flow was one sixth compared to today’s technology and heat could be recovered at high temperature.

Research reports describe the validation of the technology in principle as a first stage proof of technological concept. Furthermore, carbon dioxide of biogenic origin is obtained at close to 100% concentration. This enables carbon capture and makes electrofuels an interesting spinoff or by-product from the LimeArc process. Energy market projections using economic data provided by a Swedish pulp mill, indicate the cost of electric power is lower than that of both oil and wood pellets. The investment cost of introducing full-scale Gasplasma has previously been estimated by KTH to be about half of that for a fuel-fired rotary kiln.

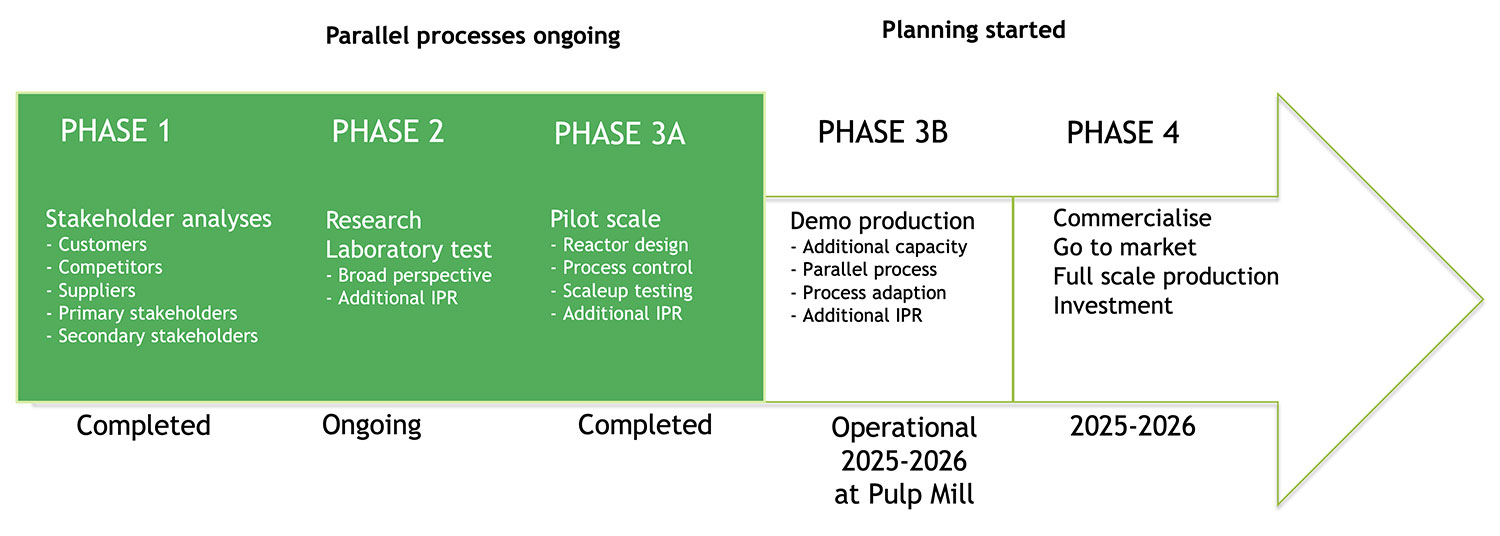

Step by step approach

LimeArc has taken a stepwise approach to ensure optimal utilization of grants together with venture capital. This has resulted in the following overall project plan:

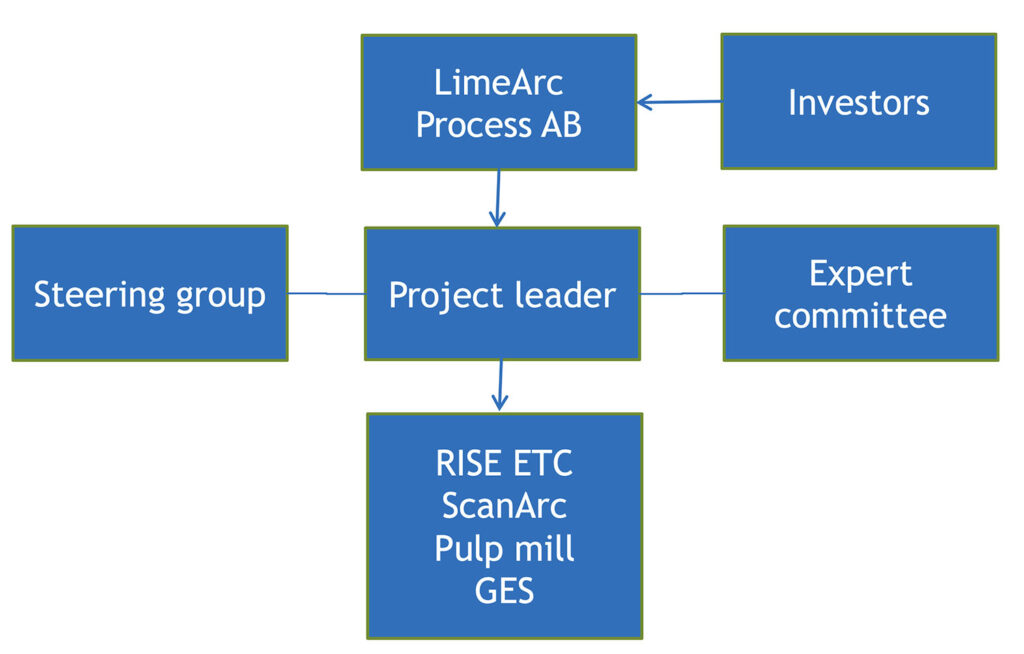

Organization

By utilizing know-how and competencies from academia, the pulp and paper industry, along with technology specialists and consultants, LimeArc has assembled a strong team and network moving forward.

Phase 1. Involving customer from start

IIt has been important to work closely with the end customer from the start, from idea generation through research at the KTH of Technology in Stockholm in collaboration with Vattenfall to early stage development together with pulp and paper companies.

A stakeholder analysis shows there is a clear understanding of needs from industry today and in the future. As we collaborate with global leading pulp and paper groups based in the Nordic Countries, LimeArc will be well prepared to enter global markets. Through these collaborations we realized adding extra capacity is interesting for the end customers with lower direct investments, lower maintenance and reduction of CO2.

Phase 2. Research Institute of Sweden (RISE) – Energy Technology Center

Henrik Wiinikka RISE ETC says

”The aim of this research project is to generate fundamental information regarding flash calcination of fine calcium carbonate particles in a hot process gas consisting of pure carbon dioxide. Development of a mathematical sub-model of the calcination process suitable for implementing in computational fluid dynamic (CFD) code is also one of the tasks.

We expect that the final CFD model can be used as a simulation tool in the near future for optimization and upscaling of the LimeArc process and thereby facilitate the commercialization of the technology.”

RISE ETC is a nonprofit research organization (RTO), and wholly-owned subsidiary of RISE that performs R&D under industrially relevant conditions providing know-how to support innovation processes. RISE provides tailor-made professional services to industry, public agencies and academia, and is already engaged in a number of Sweden’s strategic industrial initiatives.

Phase 3. Technology shift from steel to forestry industry

ScanArc Plasma Technologies AB in Hofors, Sweden develops plasma systems for the steel and metalurgical industry – as an effective and environmentally friendly technology to convert electric power into hot gas. This technology can be implemented in industrial processes requiring hot gas produced without fossil fuels. Their test facility has been an essential key resource in the development of a number of commercially operating high temperature processes. ScanArc has a flexible set-up with cooling water, various gases, power supply systems of 0,1-8 MW, gas and water cleaning equipment, material handling, etc. The plant is operated by highly skilled operators with experience in a wide range of plasma-based high temperature processes.ScanArc provided support for LimeArc’s high temperature processes in Phase 3A of LimeArc’s development plan.

• Phase 3 A is pilot-scale test in ScanArcs pilot plant performed 2023-2024 with plasma for calcination of lime mud. The aim was to analyze effects on calcination, sintering, separation, upscaling and verification of the process model with the goal to produce a quick lime compatible to the existing causticization process.

• Phase 3 B is supplementary test in the existing pilot together with ScanArc and global equipment supplier (GES) to the forestry industry to verify stability in continuous operation, followed by verification run in realistic environment at a pulp mill.

Phase 4. Market entry for global markets starts in the Nordic region

We plan to enter the market through a stepwise approach in close relationships with established operators in this field through our own established market connections and contacts. By involving end customers early on in laboratory and field tests and customizing the processes to their demand, we aim to establish trust, facilitating easier entry into existing production lines.

The market LimeArc’s process is international, we believe our first entry will be for mills who are increasing their production volumes and adding new capacity. Following this we will focus on mills that plan to replace old equipment with expired plant and equipment. Together with global equipment supplier (GES) to the forestry industry we are able to offer full engineering solutions to all pulp mills. In line with our development plan we foresee being ready for a commercial production set-up and operation at a partnering paper and pulp mill.